Home » Products » Developer/Cleaner » Apogee 450 Spin Developer – Benchtop

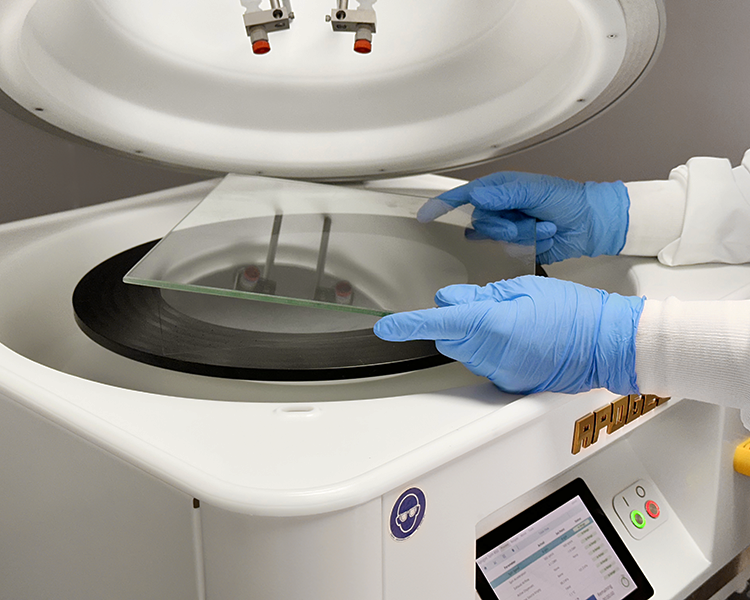

The Apogee® 450 Spin Developer is designed to handle your large, heavy substrates with high torque, an expanded bowl capacity, and modern controls. Its sleek tabletop design seamlessly integrates into any lab or fabrication environment, helping you scale and optimize your processes.

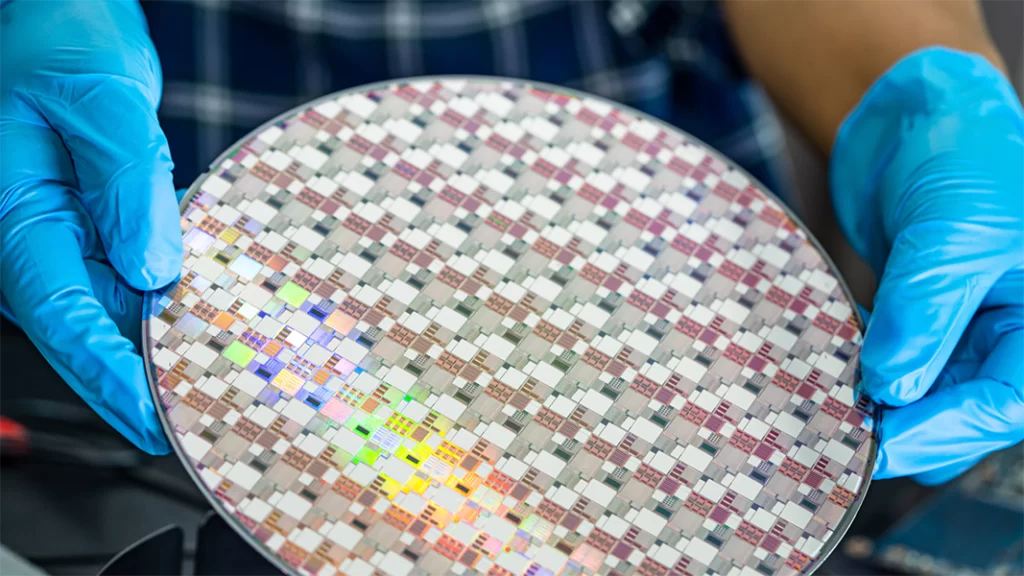

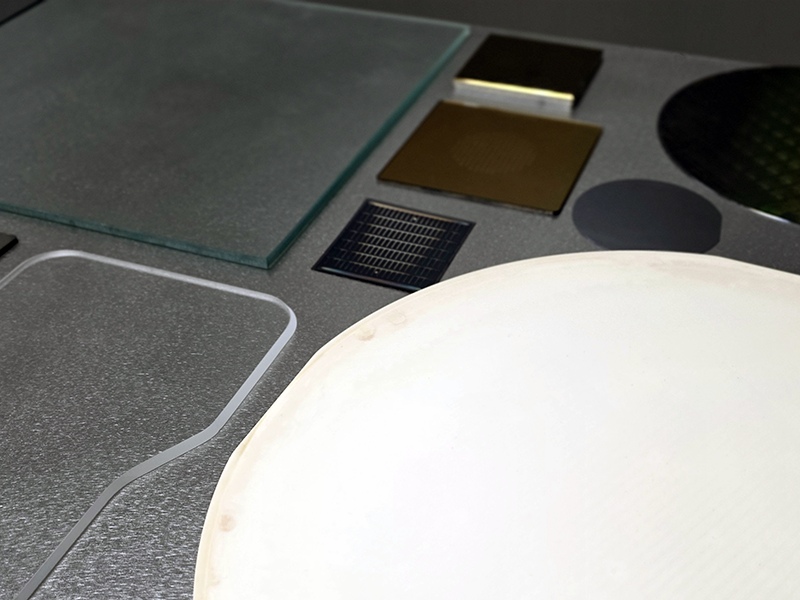

Ultra-thin wafers, film frames, photomasks, and custom shapes?

Unconventional doesn’t have to be complicated. The Apogee® 450 Spin Developer is the perfect solution for research labs and manufacturers dealing with custom dimensions. Effortlessly handle sizes and shapes beyond typical semiconductor standards.

Apogee® Spin Developers provide flexibility, repeatability, and long-lasting durability for the most challenging applications. Rely on cutting-edge technology and top-tier process support to drive your success at every stage.

Engineered for superior performance, usability, versatility—and peace of mind.

On-board 7-inch color touchscreen with DataStream™ OS included for visibility and your ease-of-use.

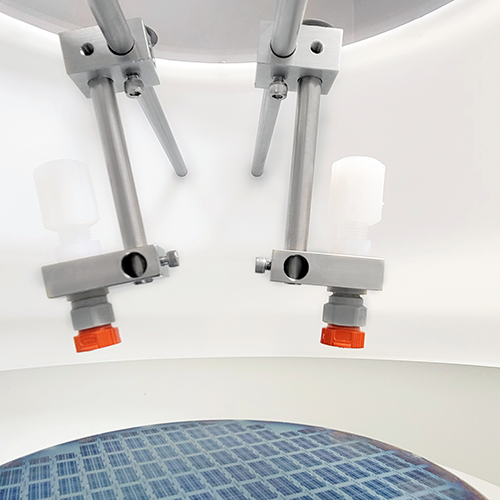

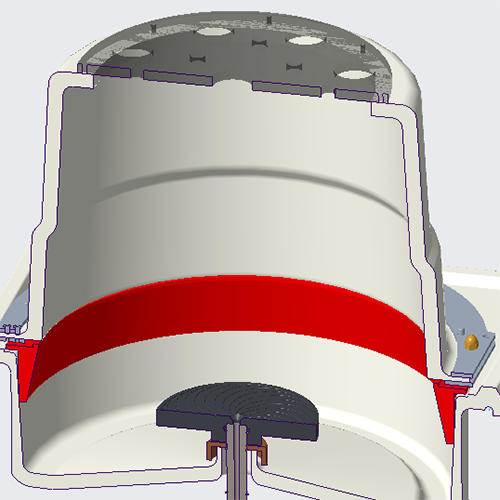

Integrated splash ring prevents droplets from redepositing onto the wafer for a contamination-free surface and defect-free results.

A brushless motor and indirect drive with oversized bearings/belt provide unmatched uptime, thermal isolation, and performance.

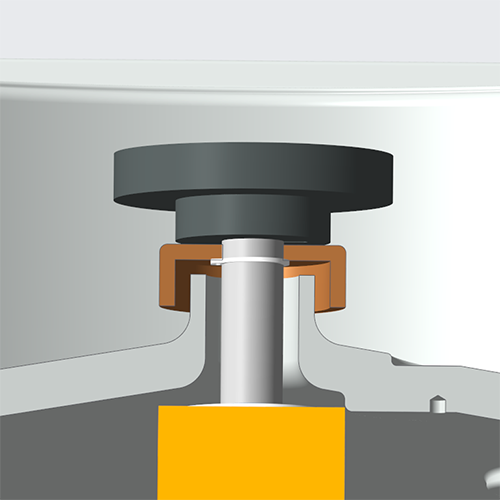

The built-in spindle fluid deflector keeps liquids out of your drive train and bearings, without purge gases.

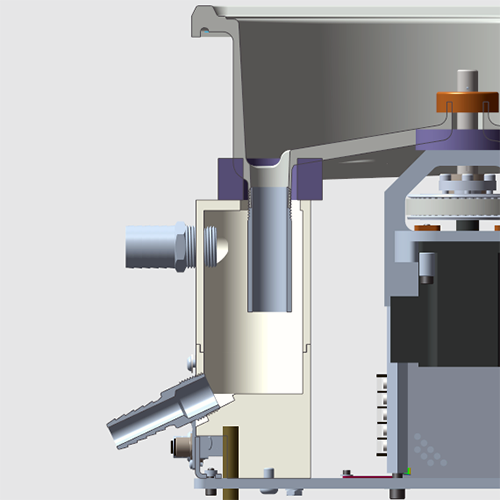

Integrated PFA fluid trap protects your vacuum components and pumps from unwanted contamination and blockage.

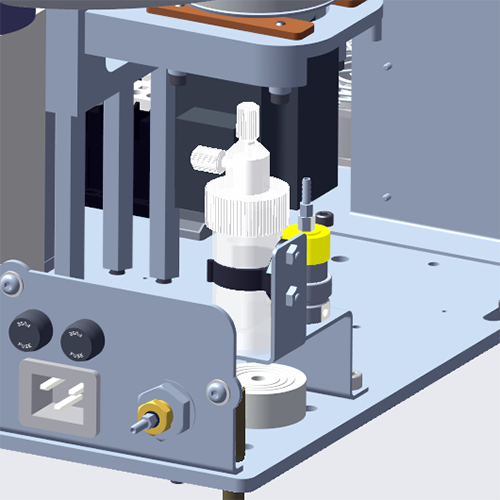

Sophisticated fluid separator evacuates chemical fumes while safely guiding fluid waste to the drain.

Knowledge is power. With DataStream™ technology, monitor and manage in real time, ensuring production-quality results from anywhere. Proactive warnings and detailed log files give you the information you need to succeed.

Process parameters and measurements are logged in real-time. Export in multiple formats for analysis, troubleshooting, and process optimization.

Access your Apogee® Spin Developer remotely via any web browser for real-time monitoring, adjustments, and recipe management. Create, modify, upload, download, and archive recipes seamlessly.

NRTL certification is crucial for semiconductor equipment, ensuring compliance with safety standards set by regulatory bodies like OSHA and ANSI.

Cee® spin developers are NRTL listed right out of the box…

…your safety department is going to love you.

When advanced processes require advanced features, Cee® has you covered. Personalize your spin coater right from the factory.

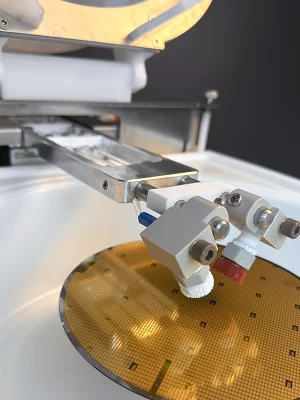

Discover a whole new level of control with AccuScan™ Dispense; a programmable scanning arm offering precision dispense and edge bead removal.

Got incompatible materials? Divert, isolate, and route waste through multiple paths. Switch mid-process with recipe-controlled functionality.

Challenge accepted! Any size, shape, material, or design, Cee® tailored spin chucks are expertly matched to your substrates.

450mm Round or 14″ x 14″ Square

6,000 rpm

30,000 rpm/s

0.2 rpm

< 0.2 rpm/s

0.2 rpm

7″ Full Color Touchscreen

Unlimited

0.1 s

8115 lb (52.2kg)

220 lb (100kg)

W: 27.625″ (702mm)

D: 30.75″ (710mm)

H: 23.5″ (597mm)

W: 34″ (864mm)

D: 34″ (864mm)

H: 38″ (965mm)

208-230 VAC

3/4″ OD

6A (max)

1.5″ OD, 0.4″ H2O @ 30CFM (100Pa @ 50CMH)

1/4″ Push to Connect, <20″ Hg (33kPa)

1/4″ Push to Connect, 70psi (482kPa)

With four decades of experience, our experts will collaborate closely with you to understand your requirements and deliver solutions that exceed expectations.