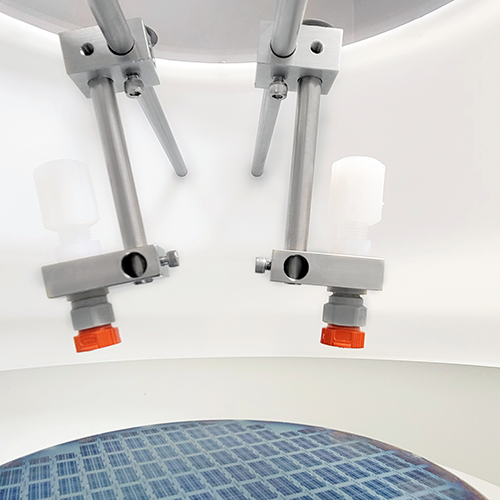

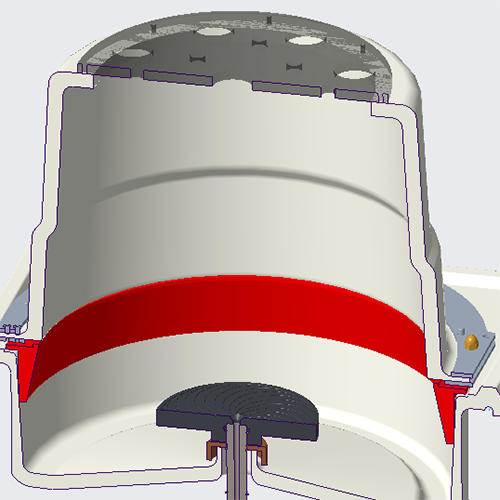

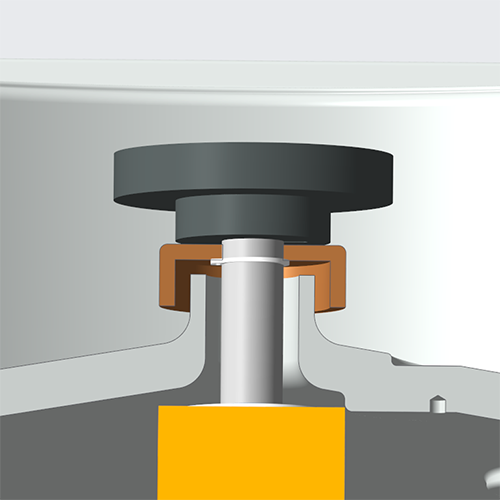

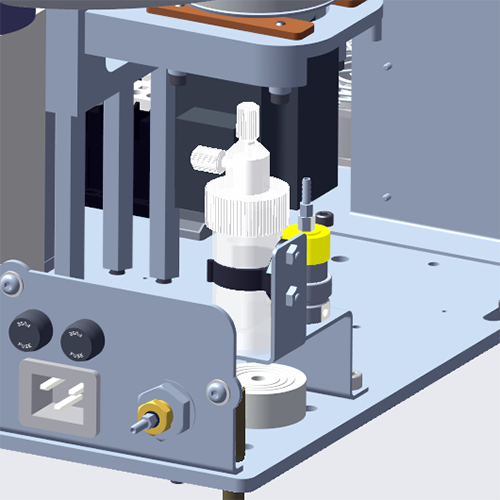

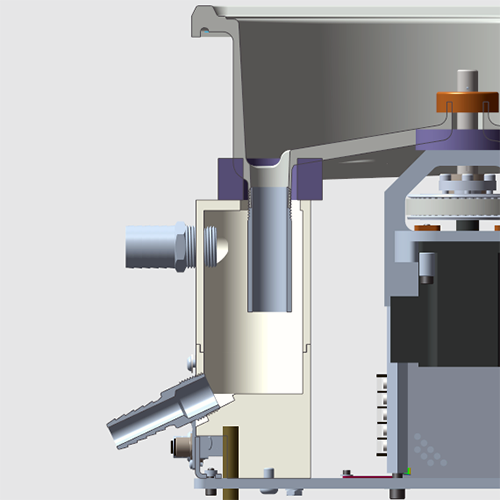

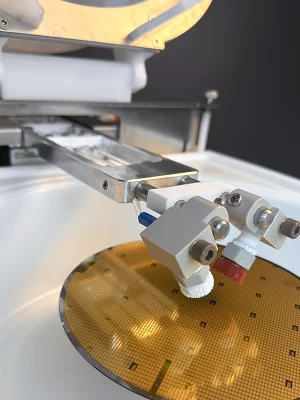

Imagine a tidy, efficient environment where you can focus on what really matters. The Apogee® Spin Developer’s sleek, flush-mount design keeps critical hardware hidden under the deck, maximizing your workspace and offering a clear view of operations.